REGULATIONS:

Many health and safety regulations worldwide such as COSHH in the UK and OSHA in the USA state that:

“the employer must not expose personnel to substances that are hazardous to health”

and

“should constantly monitor process exhaust gases for fume and particulate levels”

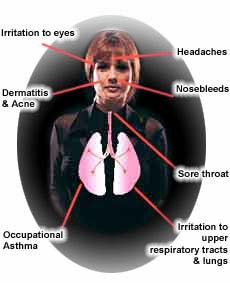

Personnel who are exposed to hazardous material can develop long term, serious medical conditions and it is the employer who may face expensive compensation claims as a result. Links to regulations in different countries can be found on the left

KEY TOXICOLOGICAL ELEMENTS PRODUCED DURING SOLDERING:

In order to design a safe extraction and filtration system, we need to understand what fumes are emitted when soldering and what the characteristics of the particles and gas are.

Solder fume can contain many of the compounds shown below, of which approximately 99.5% are particles and 0.5% are gases. The design of any filtration system should take these facts into account as these fumes can pose a serious danger to the health of employees who are exposed to them.

- Lead oxide

- Carbon monoxide

- V.O.C (volatile organic compounds)

- Abietic acid

- Pimaric acid

- Aliphatic aldehydes

- Hydrochloric acid

- Isocyanates

- Isopropyl alcohol

|